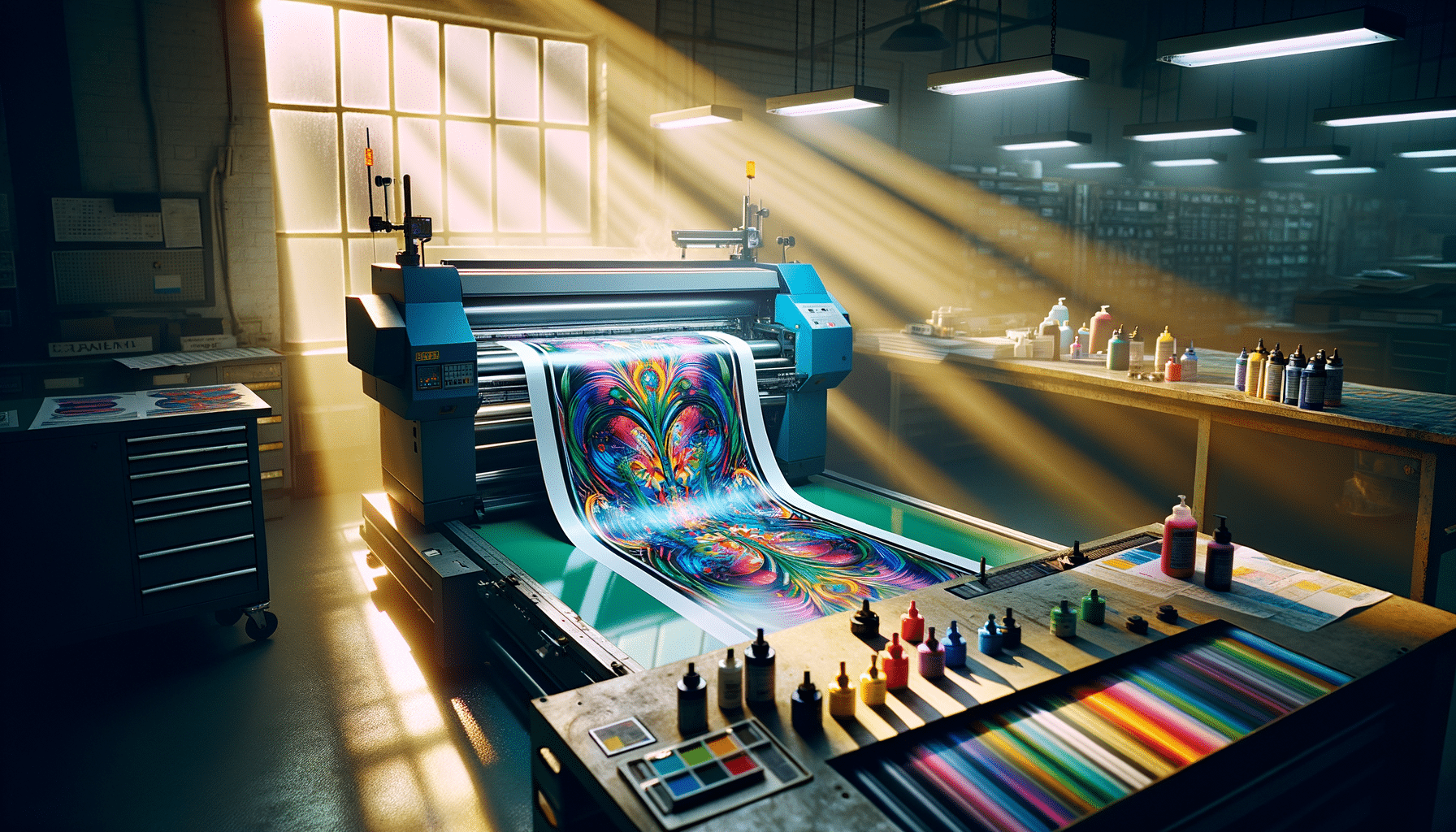

DTF Printer

Introduction to DTF Printing Technology

Direct to Film (DTF) printing technology has emerged as a transformative method in the world of custom printing, offering a unique approach to transferring designs onto a variety of materials. Unlike traditional methods, DTF printing involves printing a design onto a special film, which is then transferred onto the desired surface using heat and pressure. This technology is renowned for its versatility and ability to work on diverse substrates, making it a popular choice among businesses and hobbyists alike.

DTF printing technology stands out due to its ability to produce vibrant, high-quality prints that can adhere to fabrics, ceramics, and even metals. The process begins with creating a digital design, which is then printed directly onto a PET film. A special adhesive powder is applied to the wet ink, allowing the design to bond effectively with the target material. This method not only provides durability but also ensures that the printed designs maintain their vibrancy and detail over time.

One of the key advantages of DTF printing is its flexibility. It allows for printing on both light and dark fabrics without the need for pre-treatment, unlike some other methods that require extensive preparation. Additionally, the technology supports a wide range of colors, enabling intricate designs with gradients and fine details to be reproduced accurately. The ease of use and the ability to produce high-quality results make DTF printing an attractive option for those looking to expand their printing capabilities.

Benefits of Using DTF Printers

DTF printers offer a plethora of benefits that make them a preferred choice for many printing professionals and enthusiasts. One of the most significant advantages is the exceptional print quality they deliver. The technology allows for high-resolution prints that capture intricate details and vibrant colors, making it ideal for creating custom apparel, promotional items, and personalized gifts.

Another notable benefit of DTF printers is their versatility. They can print on a wide array of materials, including cotton, polyester, leather, and more, without compromising on quality. This capability opens up numerous possibilities for businesses looking to diversify their product offerings. Additionally, the use of adhesive powder in the DTF process ensures strong adhesion of the print, enhancing its durability and resistance to washing and wear.

DTF printers are also known for their efficiency and cost-effectiveness. The process eliminates the need for multiple steps and extensive labor, which can be time-consuming and costly in traditional printing methods. By streamlining the workflow, DTF printers enable faster turnaround times and reduced production costs, making them an economical choice for both small-scale and large-scale operations.

- High-resolution prints with vibrant colors

- Ability to print on various materials

- Durable and resistant to wear

- Cost-effective and efficient production

Applications of DTF Printing

DTF printing technology has found numerous applications across different industries due to its adaptability and high-quality output. In the fashion industry, it is widely used for producing custom T-shirts, hoodies, and other apparel items. The ability to print complex designs with fine details and vibrant colors makes DTF printing ideal for creating eye-catching fashion pieces that stand out in the market.

In addition to fashion, DTF printing is also popular in the promotional products industry. Companies often use DTF printers to create branded merchandise such as bags, caps, and mugs, which serve as effective marketing tools. The durability of DTF prints ensures that the branding remains intact even with frequent use, enhancing the visibility and impact of promotional campaigns.

Another emerging application of DTF printing is in the home décor sector. With the ability to print on various surfaces, DTF technology is used to create custom wall art, cushions, and other decorative items that add a personal touch to living spaces. The versatility of DTF printing allows designers to experiment with different materials and textures, offering unique and customized products to consumers.

Comparing DTF with Other Printing Methods

When comparing DTF printing to other popular methods such as screen printing and direct-to-garment (DTG) printing, several distinctions become apparent. Screen printing is known for its durability and cost-effectiveness when producing large quantities, but it lacks the flexibility and detail that DTF offers. Screen printing requires separate screens for each color, making it less suitable for designs with multiple colors and intricate details.

On the other hand, DTG printing shares some similarities with DTF in terms of printing directly onto fabrics. However, DTG is typically limited to cotton and cotton-blend materials and often requires pre-treatment of the fabric, which can add to the production time and cost. DTF printing, by contrast, can be applied to a wider range of materials without the need for pre-treatment, offering greater versatility and efficiency.

While each printing method has its own advantages and ideal use cases, DTF printing stands out for its ability to combine high-quality output with versatility and efficiency. This makes it a compelling option for businesses and individuals seeking to explore new creative possibilities in custom printing.

- Screen printing: Durable but less flexible and detailed

- DTG printing: Limited to specific materials, requires pre-treatment

- DTF printing: Versatile, efficient, suitable for detailed designs

Conclusion: The Future of DTF Printing

As technology continues to evolve, DTF printing is poised to play an increasingly significant role in the custom printing landscape. Its ability to deliver high-quality prints on a wide range of materials, combined with its efficiency and cost-effectiveness, makes it a valuable tool for businesses and creative individuals alike. Whether for fashion, promotional products, or home décor, the applications of DTF printing are vast and varied.

Looking ahead, advancements in DTF printer technology and materials are likely to further enhance the capabilities and appeal of this printing method. As more businesses and consumers recognize the benefits of DTF printing, its adoption is expected to grow, driving innovation and expanding the possibilities for custom printing solutions. For those seeking to stay at the forefront of printing technology, embracing DTF printing could be a strategic move that offers both creative freedom and competitive advantage.